Additional Resources

learn more

Media Library

IMAGES & GRAPHICS

Background Documents

- CLIA Fact Sheet on Exhaust Gas Cleaning Systems (EGCS)

- Carnival Corporation's Sustainability Reports

- IMO Infographic on Five Beneficial Changes from IMO's Sulphur Limit for Ships' Fuel Oil

- IMO 2021 Guidelines for Exhaust Gas Cleaning Systems

- CLIA Infographic on Exhaust Gas Cleaning Systems – Cruise Line Innovations Help Reduce Air Emissions

- CLIA Environmental Technologies and Practices

- CLIA Environmental Protection and Stewardship

- CLIA Charting the Future of Sustainable Cruise Travel Report

- Exhaust Gas Cleaning Systems Association Editorial Piece: Hype over open loop scrubber discharges risks loss of key issue

Scientific Research

- Comparison of CO2 emissions of MARPOL Annex VI Compliance Options in 2020 – CE Delft

August 2020 - The Impacts of EGCS Washwater Discharges on Port Water and Sediment – CE Delft

December 2019 - Compilation and Assessment of Lab Samples from EGCS Washwater Discharge on Carnival ships – DNV GL

February 2019 - Compilation and assessment of 281 cruise ship EGCS washwater samples – CLIA Submission to IMO

March 2019 - Washwater Discharge from Open-Looped SOx Scrubber System – Japan Ministry of Land, Infrastructure, Transport and Tourism

February 2019

- Measurements of Abatement of Particles and Exhaust Gases in A Marine Gas Scrubber – Erik Fridell and Kent Salo

July 2014 - Investigation of appropriate control measures (abatement technologies) to reduce Black Carbon emissions from international shipping – Litehauz in co-operation with Daniel Lack, Jørgen Thuesen and Robert Elliot

November 2012 - Use of Seawater Scrubbing for SO2 Removal from Marine Engine Exhaust Gas – Anders Andreasen and Stefan Mayer

October 2007 - Assessment of possible impacts of scrubber water discharges on the marine environment – Danish Environmental Protection Agency

2012

FAQ

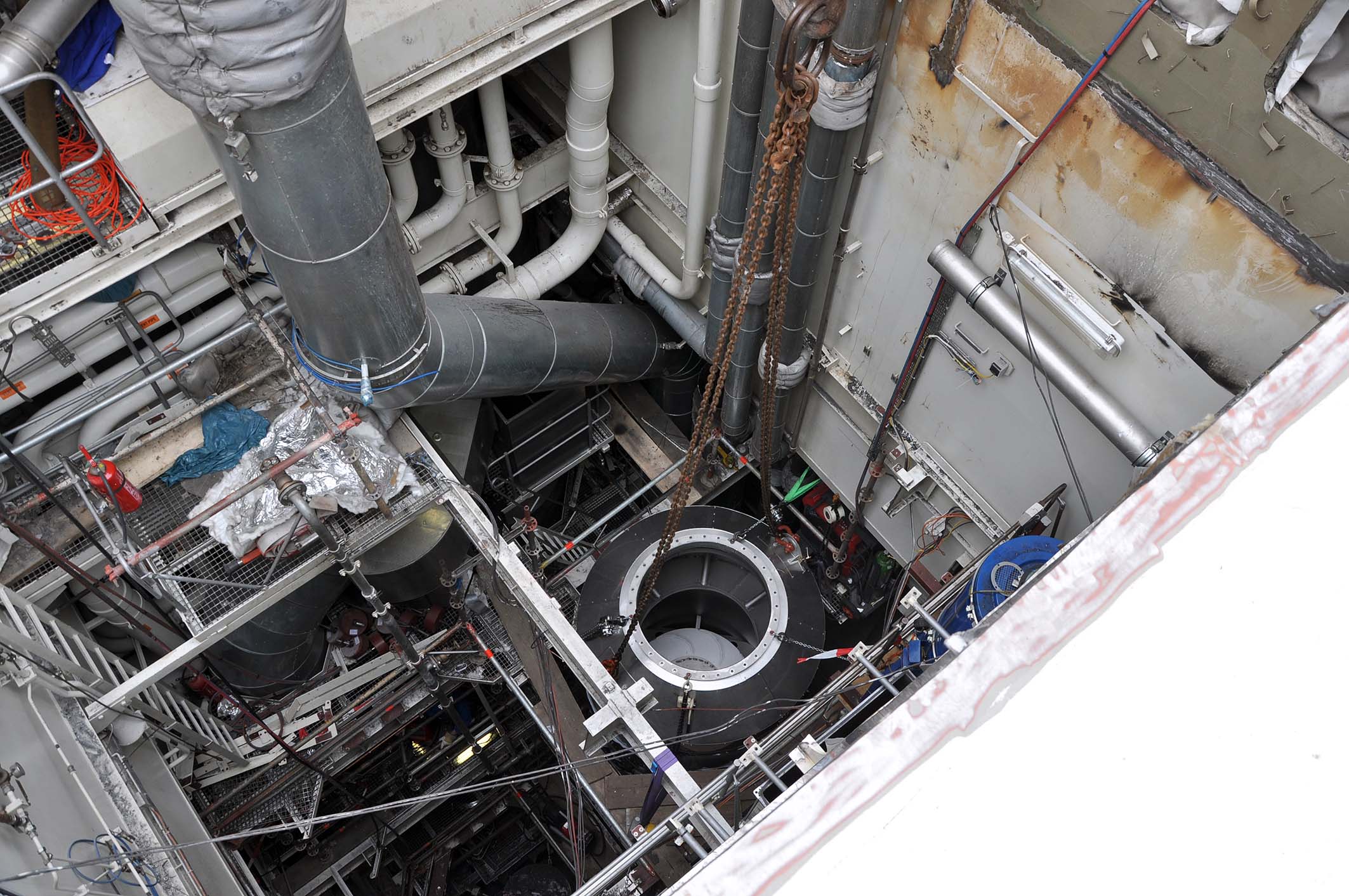

- The basic system is a pump, two pipes and an exhaust gas cleaning tower.

- Seawater is pumped to the tower, which replaces the engine exhaust silencer.

- Seawater is sprayed into the tower, where it cleans the exhaust from the ship’s engines, removing SOx, mainly SO2.

- The seawater drains from the tower and (in port) through a filter before discharge.

- Any remaining SO2 is measured by a gas analyzer above the tower.

- The seawater used is measured continuously for pH, turbidity, and PAH (oil content) in three locations (inlet, after tower, and before discharge).

- The Advanced Air Quality Systems remove sulfur (SOx) from the air emissions, preventing the airborne part of the sulfur cycle.

- The Advanced Air Quality Systems also remove a high percentage of particulate matter (PM) with good effectiveness against the 10- and 2.5-micron particles and superfines.

- Diesel particulate filters (“dry filters”) also reduce PM, with particular effectiveness reducing PAH.

- Advanced Air Quality Systems with HFO have produced better air emissions than MGO, with much lower cost.

- Advanced Air Quality Systems with HFO have typically lower sulfur (SO2) emission levels, fewer ultrafine PMs and fewer PAHs than MGO.

- Marine diesel engines are factory configured for HFO and are less efficient on MGO, leading to less CO2 release per unit kilowatt (kW) power generated than using MGO.

- MGO has a higher greenhouse gas emissions (GHG) penalty in production, as more refining is needed.

- Advanced Air Quality Systems release miniscule amounts of material in the water, which is not harmful, and in the case of sulfur, it is naturally occurring in the ocean.

- The concern from sulfur and PM/PAHs is from airborne impact.

- The sea is the planet’s natural reservoir for sulfur and there is no environmental impact from discharging sulfates.

- The small amount of soot discharged contains minute amounts of PAHs and metals, which are measured in ppb (parts per billion) and are within all major water discharge standards. This means negligible environmental impact.

- Typically this is not smoke but a “white plume,” which is condensation of the water vapor entrained in the exhaust from the scrubbing process. This normally dissipates a few meters beyond the stack.

- Occasionally we also see some “blue plume,” which can be more persistent. This is from light effects on remaining compounds in the exhaust, and we are working to further reduce this as well.

- This is bubbles and foam caused by the agitation of seawater from the Advanced Air Quality Systems discharge, or “surface effects.”

- This may also often be seen from the engine cooling water discharge.

- When running Advanced Air Quality Systems outside of U.S. waters without dilution water, as in Canada or Europe, you will normally see a few bubbles and occasionally also a light film.

- When running Advanced Air Quality Systems in U.S. ports, with dilution water, normally a longer discharge plume two to three meters beneath the surface may be seen, or a small cloud of microbubbles.

- Occasionally excess gas in the system combined with high levels of dilution water will also create a surface agitation that creates seafoam, a natural phenomenon from agitated seawater that is often also found at the beach. We have observed that the foam dissipates quickly but when it breaks down a residual thin surface film is often temporarily visible.

- High organic content in the water (e.g. algae) may lead to a brown or black foam appearance. This is most common in mid-summer to late summer as water temperatures warm up.

- Lab tests of these discolored “surface effects” have typically shown zero or only trace evidence of oil, but often have high organic content.

- Open loop brings in seawater for “scrubbing” the exhaust and discharges it immediately back to sea, filtered or unfiltered.

- Closed loop recirculates the seawater, adding chemicals as the seawater alkalinity becomes saturated. Some seawater is bled off to a storage tank, where it is filtered and dewatered for later discharge at sea or sludge offload to designated facilities.

- The most common closed-loop chemical is caustic soda, which is highly toxic and requires careful storage and handling by trained personnel.

- Closed loop exhaust plume is usually much more visible than open loop.

Latest Carnival Corporation AAQS News

- Carnival Corporation Releases Third-Party Study Confirming Advanced Air Quality Systems Are Positive for Environment

March 6, 2019 - Carnival Corporation's Environmental Leadership Earns Global Recognition (Mentions AAQS)

December 21, 2018 - Carnival Corporation Releases 2017 Sustainability Report, Meets Goal to Reduce Carbon Footprint Ahead of Schedule (Mentions AAQS)

July 19, 2018 - Carnival Corporation Wins Top Global Award for Best Sustainability Report (Mentions AAQS)

June 12, 2017 - Carnival Corporation Recognized for Leadership in Environmental Excellence (Mentions AAQS)

May 15, 2017 - Carnival Corporation's Exhaust Gas Cleaning Technology Installed on 60 Percent of Fleet

February 27, 2017 - Carnival Corporation Issues 2015 Sustainability Report, Continues Strong Commitment to Environment and Safety

August 4, 2016 - Carnival Corporation's New Sustainability Report Highlights Key Environmental and Social Initiatives (Mentions AAQS)

January 12, 2016 - CDP Recognizes Carnival Corporation for Climate Change Transparency

November 16, 2015 - Carnival Corporation Announces 2020 Sustainability Goals

September 15, 2015 - Carnival Corporation Releases Sustainability Report, Reduces Rate of CO2 Emissions by 20 Percent

November 20, 2014 - Carnival Corporation Multi-Year Fuel Conservation Program Expected to Save More Than One Billion Gallons of Fuel and Reduce Carbon Emissions by 12 Billion Kilograms by End of 2014

October 2, 2014 - Carnival Corporation Significantly Increases Installations of Industry-First Exhaust Gas Cleaning Technology, Expands to More Than 70 Percent of Fleet

May 22, 2014 - Carnival Corporation Celebrates Earth Day: Will Meet Goal to Reduce Greenhouse Gas Emissions

April 21, 2014 - Carnival Corporation Wins Second Consecutive Clean Tech Award from The New Economy

February 5, 2014 - Carnival Corporation Named Clean Tech Award Winner For Best Marine Solutions By The New Economy

December 20, 2013 - Carnival Receives Support From EPA, U.S. Coast Guard and Transport Canada to Implement Breakthrough Technology to Reduce Air Emissions

September 5, 2013