How They Work

learn more

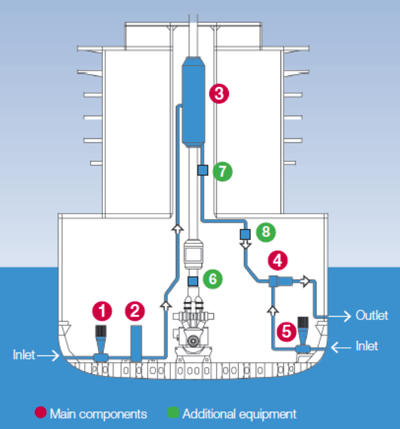

The System

The basic Advanced Air Quality System is a pump bringing seawater to an exhaust gas cleaning tower installed in a ship’s funnel. Seawater is pumped into spray arrays inside the tower, a process that removes the sulfur dioxide (SO2) and most particulate matter (PM) from the engine exhaust.

During the desulfurization process within the scrubber, SO2 gas is absorbed by the seawater spray. Through a series of natural reactions within the washwater, the SO2 is converted to an end product of sulfate (SO4), water (H2O) and carbon dioxide (CO2).

As the seawater drains from the tower, it is treated as needed to raise pH levels and then released back to the sea, meeting or exceeding all applicable water quality standards.

System Breakdown

- Seawater Pump & Variable Frequency Drive

- Seawater Filter

- DeSOx Tower

- Static Mixer

- Dilution Pump & Variable Frequency Drive

- Dry Oxidation Catalyst

- Gas Trap / De-gas Unit

- Wash-water Filtration System

Open-Loop Versus Closed-Loop

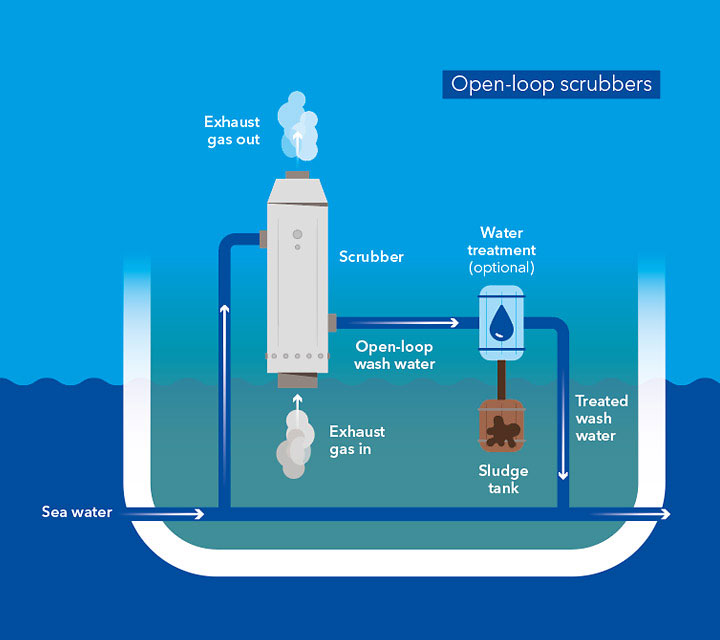

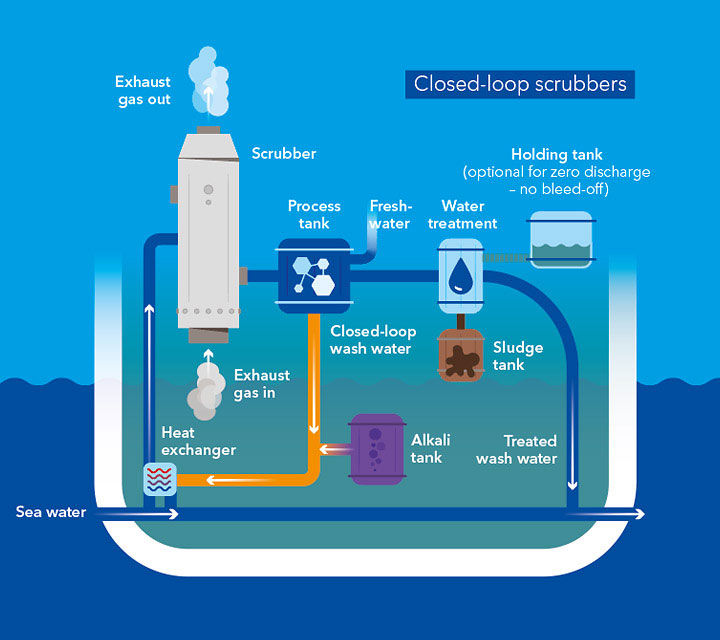

There are two main types of exhaust gas cleaning systems – open loop and closed loop – with several distinctions.

Source: DNV GL

Open-Loop

Open-loop scrubbers bring in seawater for “scrubbing” the engine exhaust prior to it leaving the ship’s funnel. The seawater is filtered and then returned to the sea in a safe and effective way, meeting all applicable water quality standards. For in-port operations, the seawater is also passed through an additional filtration process to ensure even higher water quality.

Source: DNV GL

Closed-Loop

Closed-loop and hybrid scrubbers recirculate the seawater onboard, adding chemicals such as caustic soda and producing a waste product that is generally disposed of either at a land-based facility or when at sea. These chemicals are toxic and require careful storage and handling by specially trained crew members. Generally, closed-loop operations are only conducted in port, and the systems are shifted to open loop at sea.